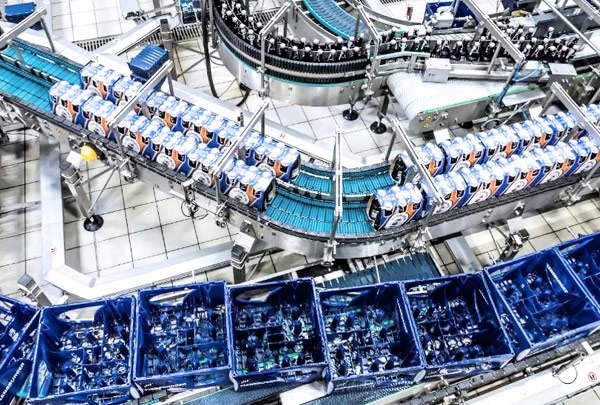

The UNITRANS series: pack conveyors, container conveyors and pallet conveyors for every performance range

BMS conveyors cover the entire conveying range of a filling plant and ensure the ideal flow of material.

BMS conveyors are custom-made, solid structures of durable stainless steel: Based on a flexible modular system and using a specially developed COP concept (carry-over parts from previous models) we are able to optimally cover the entire conveyor range of the wet and dry areas of a bottling line.

Our in-house production also offers additional advantages: we ensure an ideal flow of material without compromise – and enable further expansions even after several years. For our drives we solely used gear motors from reputable manufacturers with frequency converters and soft start features. Upon request, the conveyors can be connected to the system control via bus interface.

The BMS UNITRANS series

Product range

- Container conveyors with product-specific chains such as flat-top chains of steel or plastic or modular belts

- Special modules such as pressure-free combining, electronic blocking with single lane conveyor between two machines

- Pack conveyors with flat-top chains, modular belts or other special chains for gentle product handling

- Transfer modules for smooth transfer of sensitive packs

- Pack dividers or pack combiners

- Pallet conveyors such as e.g. roller conveyors, chain conveyors, rotary tables, end turning systems, pallet magazines, pallet lifting devices, pallet inspection systems

BMS machines

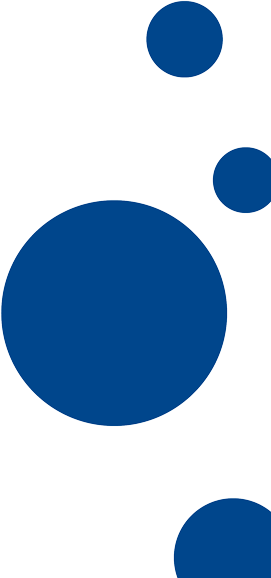

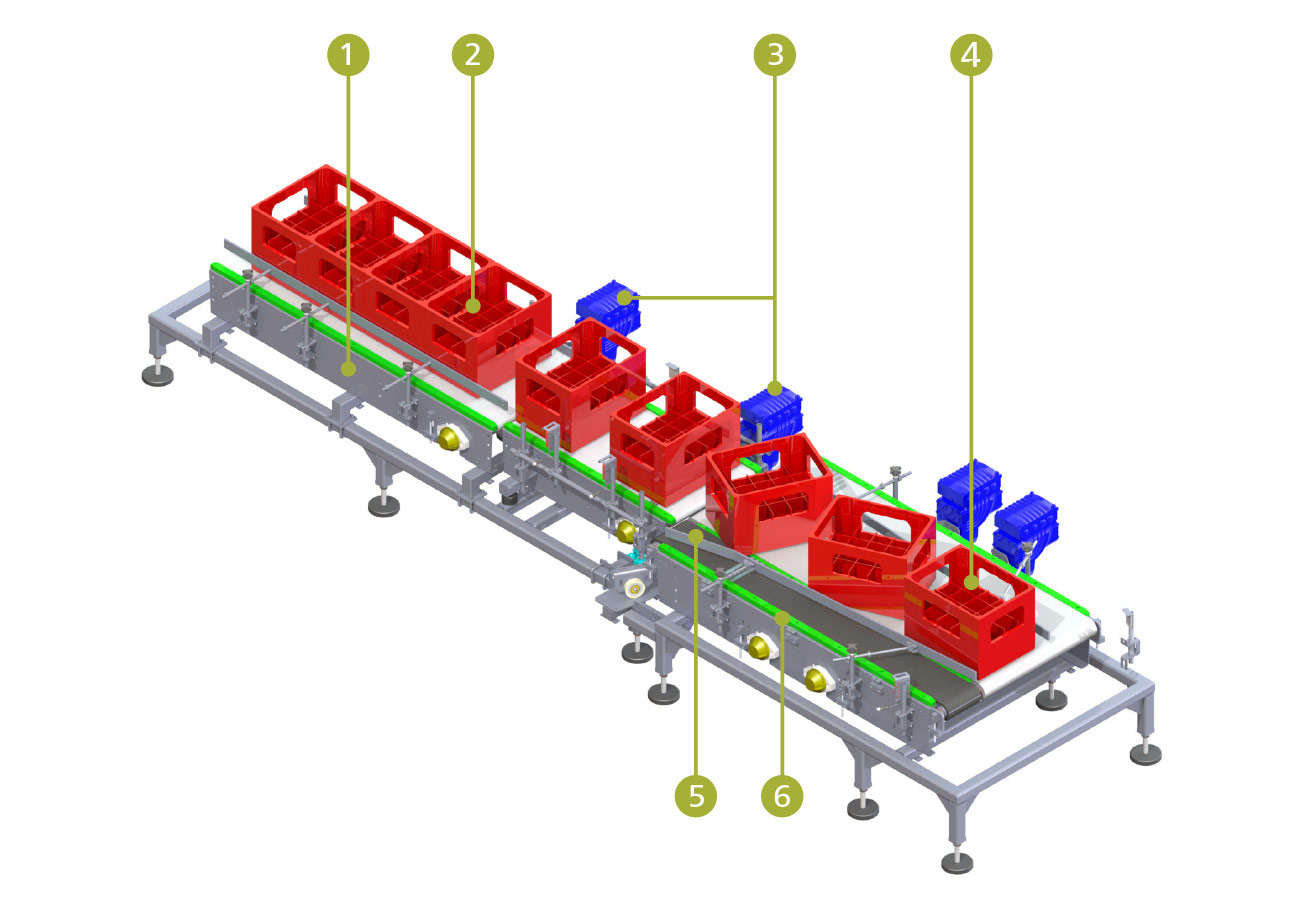

UNITRANS G

Pack conveyor with dynamic turning station

- Pack conveyor

- Pack with long side leading

- Energy-efficient drive technology

- Pack with short side leading

- Pack divider

- Turn belts with differential speed

The UNITRANS G in operation

UNITRANS G – Pack conveyor system

UNITRANS G – Pack conveyor system

UNITRANS G – Pack conveyor system

UNITRANS G – Pack conveyor system

Product range

- Container conveyors with product-specific chains such as flat-top chains of steel or plastic or modular belts

- Special modules such as pressure-free combining, electronic blocking with single lane conveyor between two machines

- Pack conveyors with flat-top chains, modular belts or other special chains for gentle product handling

- Transfer modules for smooth transfer of sensitive packs

- Pack dividers or pack combiners

- Pallet conveyors such as e.g. roller conveyors, chain conveyors, rotary tables, end turning systems, pallet magazines, pallet lifting devices, pallet inspection systems

The BMS UNITRANS series

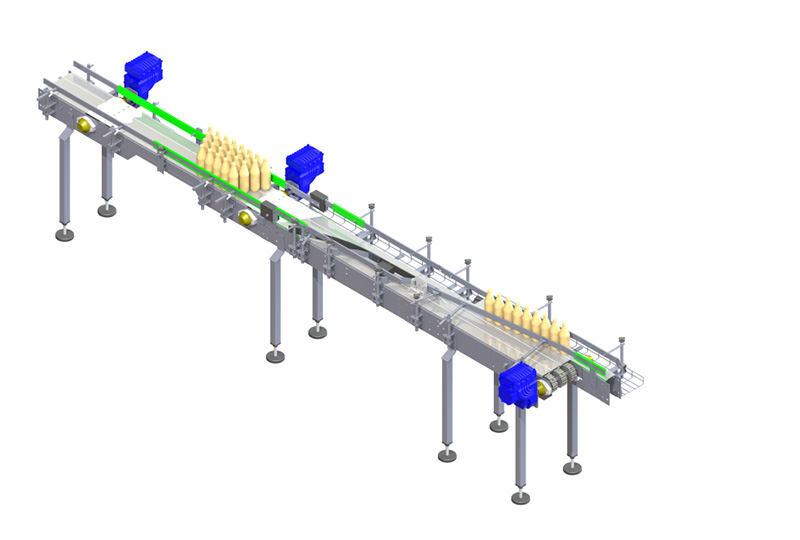

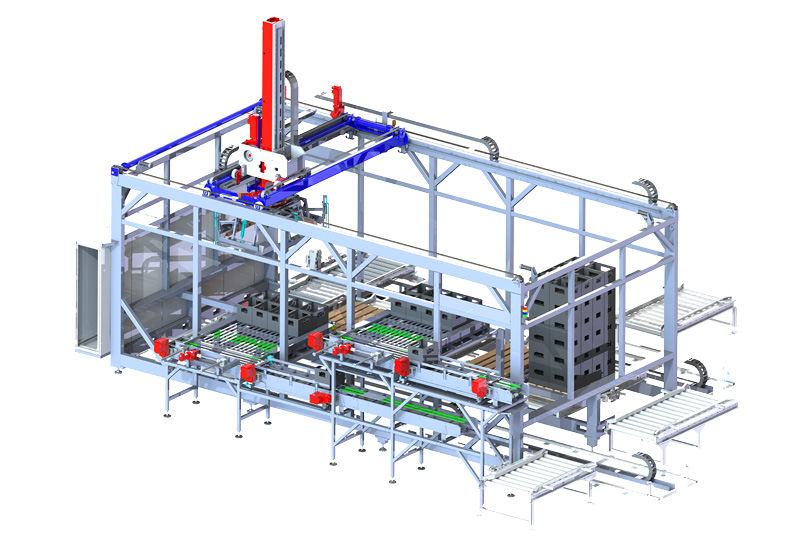

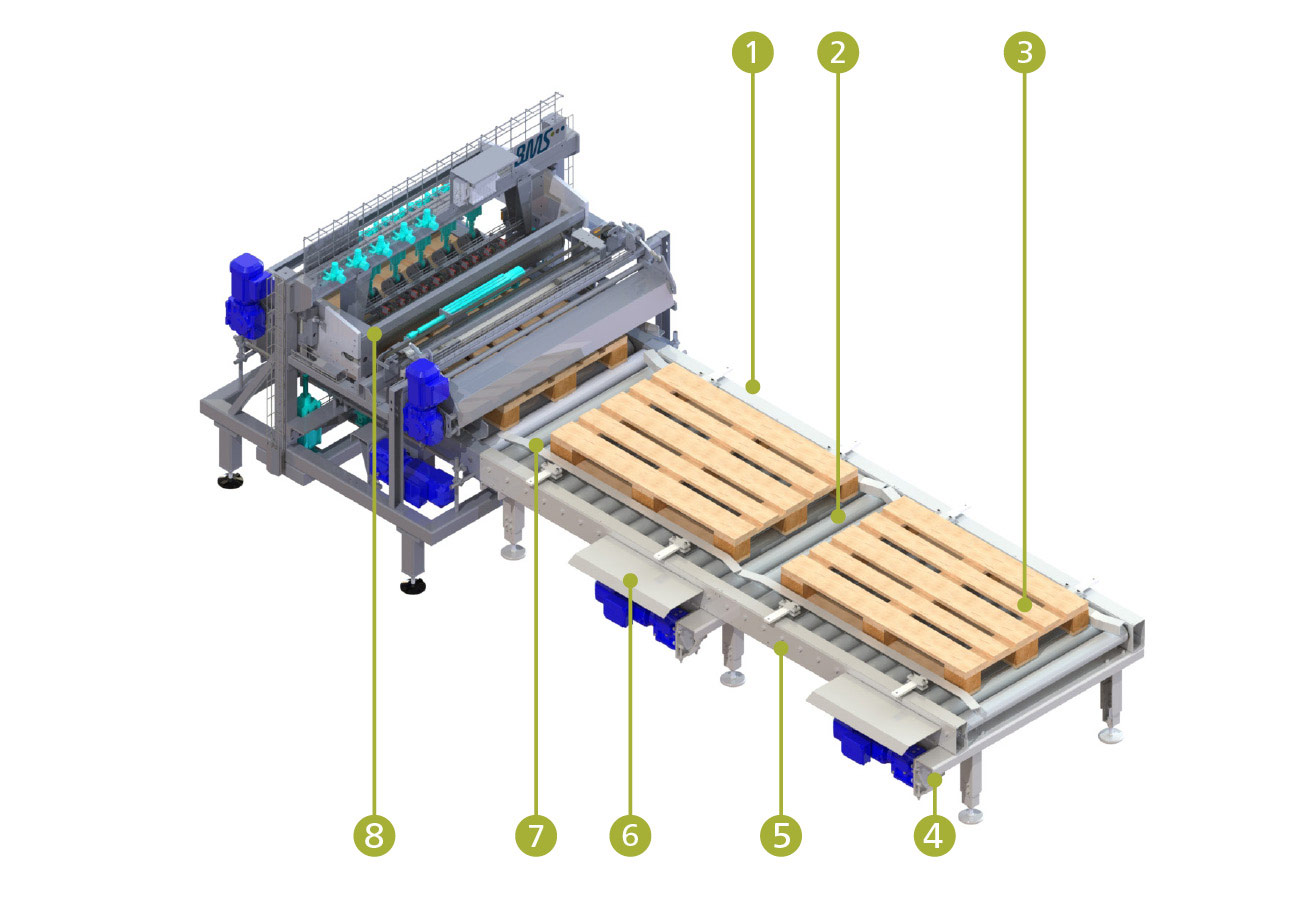

UNITRANS P

Pallet conveyor

- Pallet conveyor

- Galvanised steel rollers

- Pallet with short side leading

- Drive with worm gear

- Designed for high loads

- Cover for drives

- Adjustable pallet guide

- Pallet check

The UNITRANS P in operation

UNITRANS – Lift system over three storeys

UNITRANS – Pallet conveyor system

UNITRANS – Pallet turning station

Product range

- Container conveyors with product-specific chains such as flat-top chains of steel or plastic or modular belts

- Special modules such as pressure-free combining, electronic blocking with single lane conveyor between two machines

- Pack conveyors with flat-top chains, modular belts or other special chains for gentle product handling

- Transfer modules for smooth transfer of sensitive packs

- Pack dividers or pack combiners

- Pallet conveyors such as e.g. roller conveyors, chain conveyors, rotary tables, end turning systems, pallet magazines, pallet lifting devices, pallet inspection systems

The BMS UNITRANS series

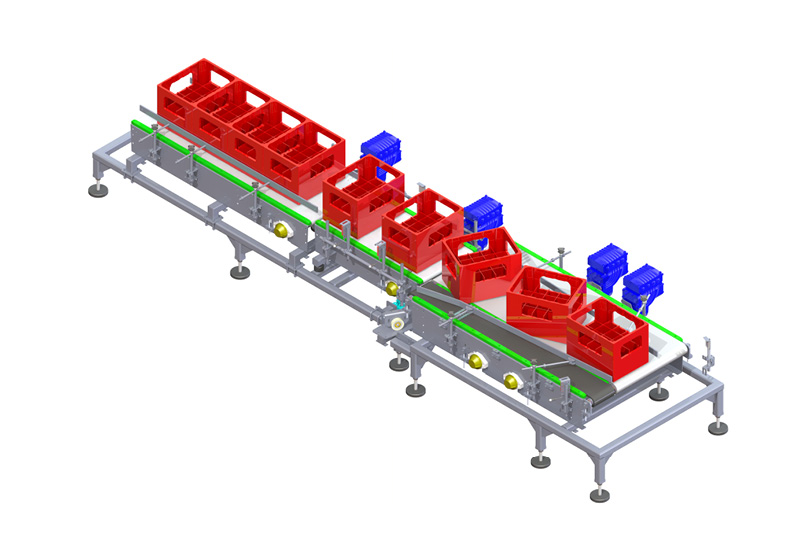

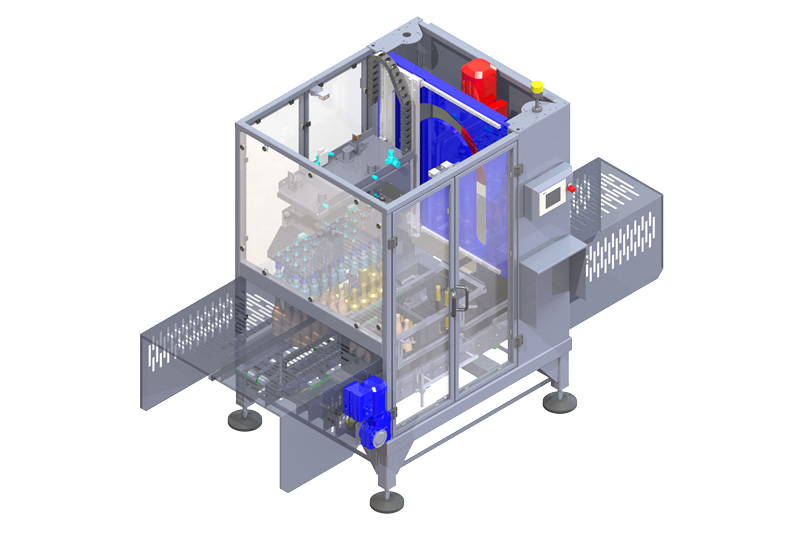

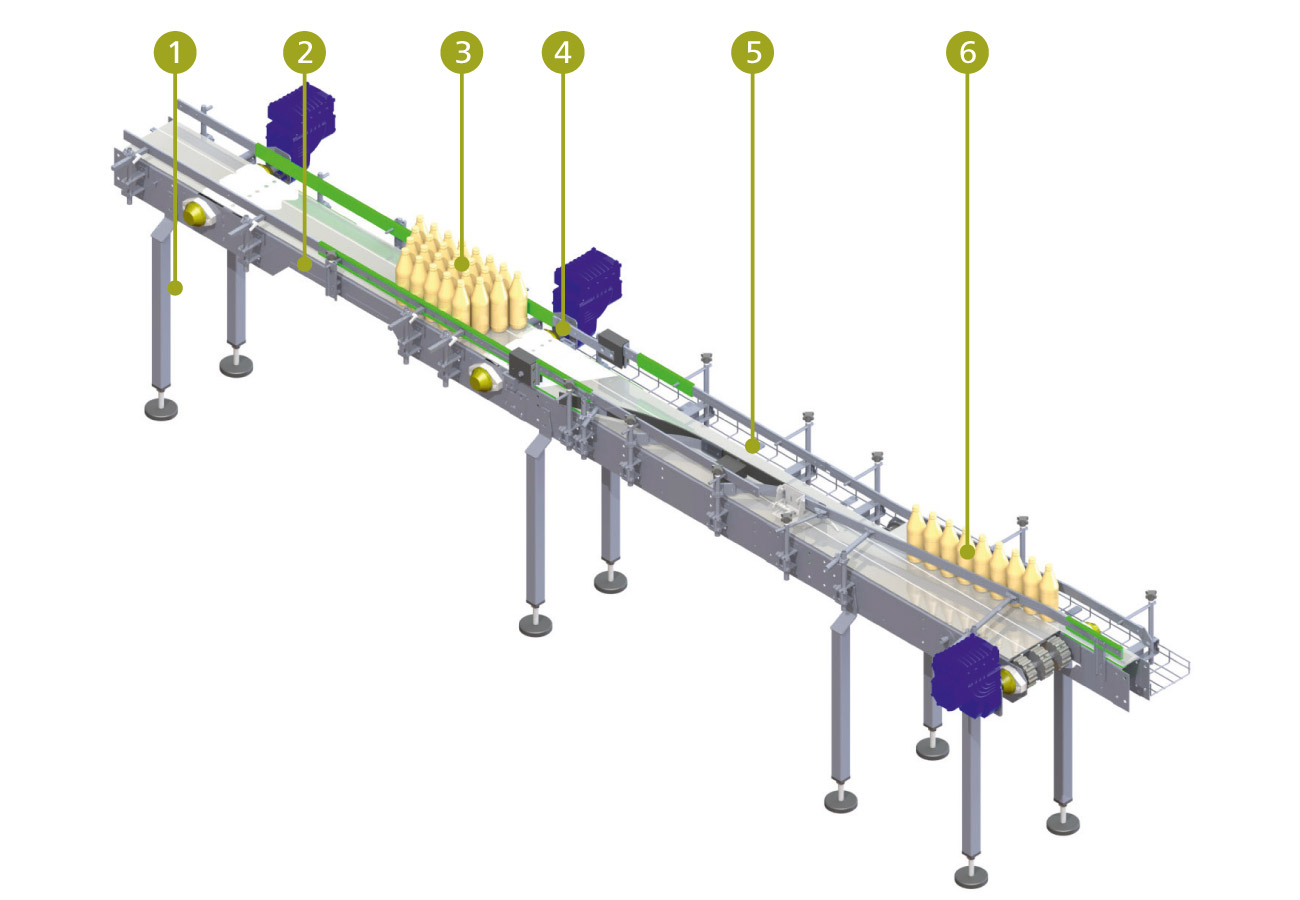

UNITRANS B

Container conveyor

- Welded stainless steel structure and levelling elements

- Container conveyor

- Multiple-lane container conveyor

- Energy-efficient drive technology

- Pressure-free container divider 360°

- Single-lane container conveyor

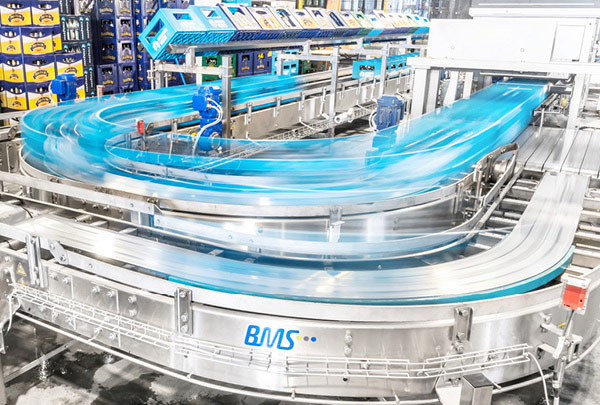

The UNITRANS B in operation

UNITRANS B – Container conveyor system

UNITRANS B – Container conveyor system

Product range

- Container conveyors with product-specific chains such as flat-top chains of steel or plastic or modular belts

- Special modules such as pressure-free combining, electronic blocking with single lane conveyor between two machines

- Pack conveyors with flat-top chains, modular belts or other special chains for gentle product handling

- Transfer modules for smooth transfer of sensitive packs

- Pack dividers or pack combiners

- Pallet conveyors such as e.g. roller conveyors, chain conveyors, rotary tables, end turning systems, pallet magazines, pallet lifting devices, pallet inspection systems

The BMS UNITRANS series

UNICONTROL P

Pallet check

- Nail roller

- Running and top board inspection

- Block control, not visible

- Stripper brush

- Control cabinet

UNICONTROL P

An independent machine with control cabinet and pallet conveyor for handling standardised Euro pallets.

UNICONTROL P can detect and roll in ALL nails with 2 nail rollers. During this process, the pressure for each inspection can be set separately. Using analogue displacement sensors the limit values can be adjusted at the control panel and the independent control means that a high level of standardisation can be attained. The checking of the blocks is contact-free.

- Basic module

· Nail rollers

· Top board pressure check

· Running board pressure check - Expansion module I

· Cleaning unit with stripper brush - Expansion module II

· Block check

· Fork clearance check

· Centring

The UNICONTROL P in operation

UNICONTROL P – Pallet checking

UNICONTROL P – Pallet checking, basic package

UNICONTROL P – Pallet checking with rotating brush

UNICONTROL P – Pallet checking

UNICONTROL P

Fault detection