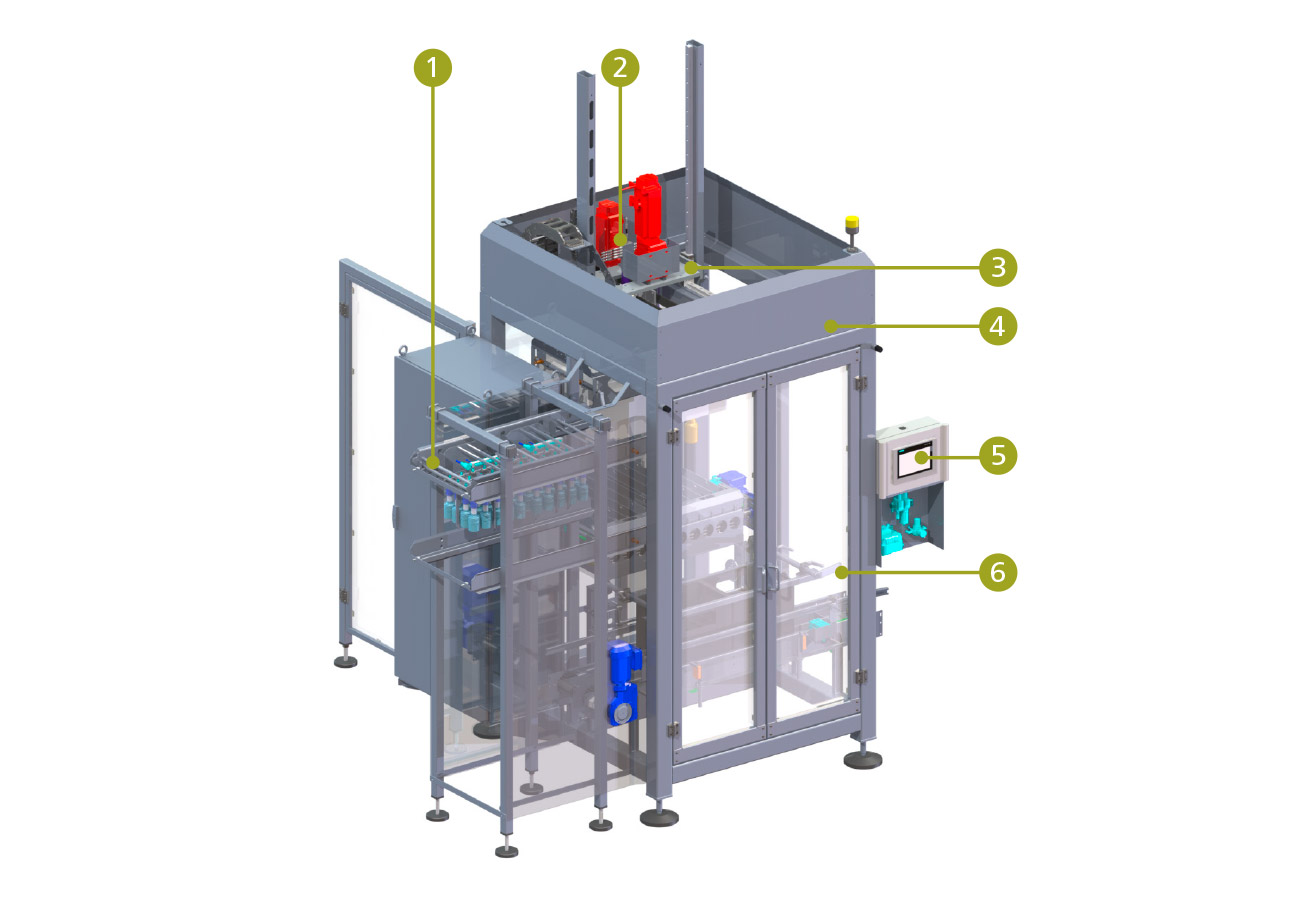

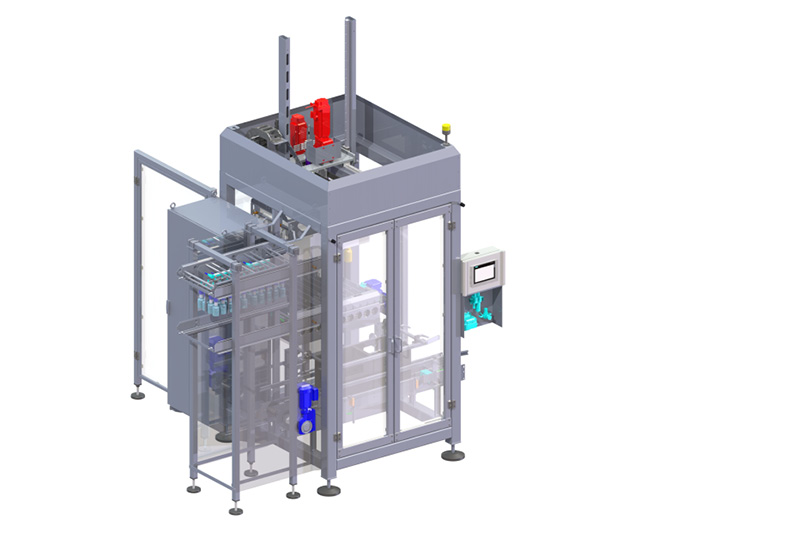

Portal-type packer

UNIPACK 2.0

With its new development of the packing machine UNIPACK 2.0 BMS has responded to the increase in variety of products and containers in the small and medium performance range. Compared to the previous model the new portal-type packer is much more powerful and can now be used for all pick-and-place applications in the brewing, beverage, dairy and food industry.

The UNIPACK 2.0 offers all advantages of the proven BMS portal design featuring maximum flexibility, short retooling times and high investment security based on the retrofit ability of the portal axis.

Other characteristic features of the UNIPACK 2.0 are its modular design, its consistent hygiene design as well as its optimised structure and operation.

- Integrated handling parts magazine

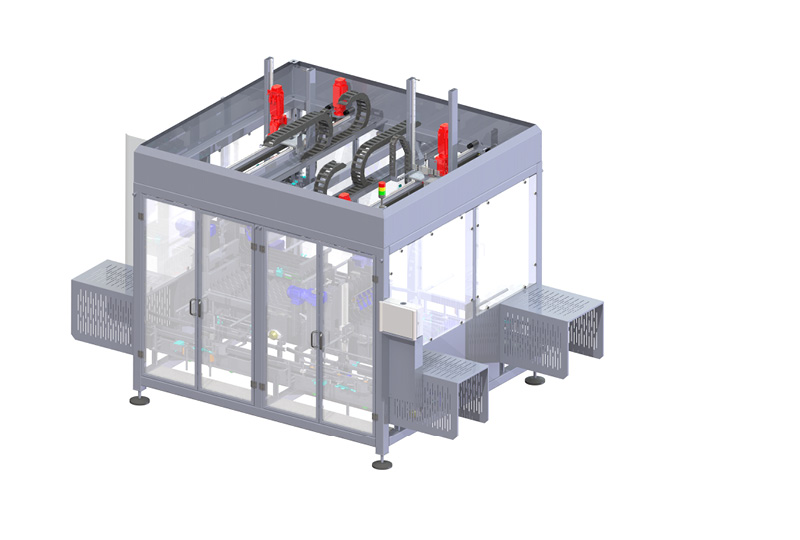

- Highly dynamic servo-drives

- Optimal load distribution based on the unique bridge-type design

- Compact, space-saving portal design

- Touch panel with intuitive user prompting and logical diagnostics feedback

- Integrated machine protection

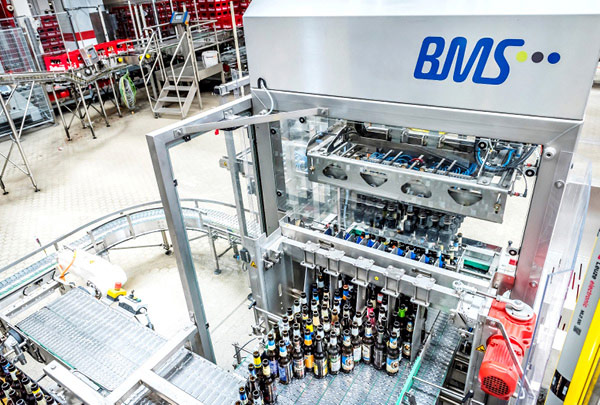

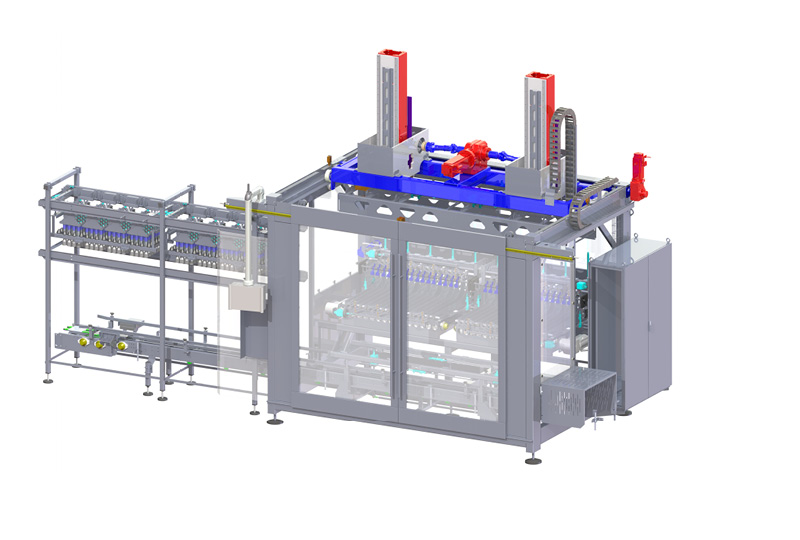

BMS portal-type machine UNIPACK 2.0 in operation

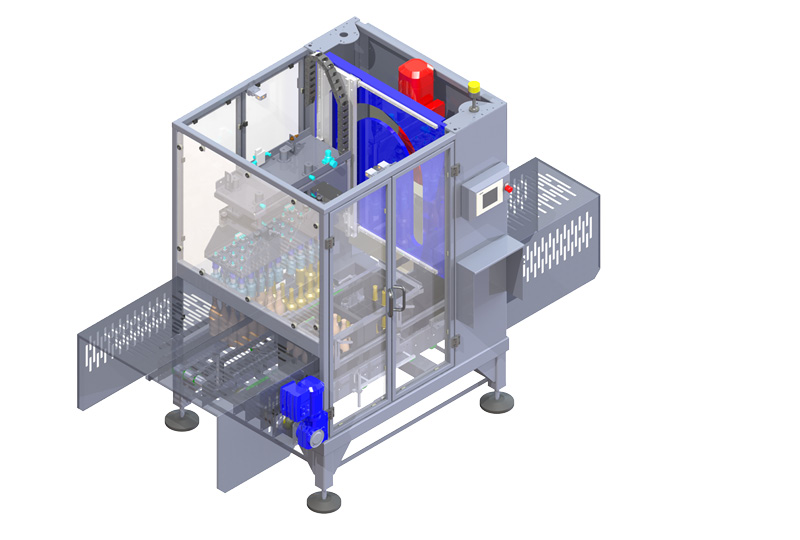

Packer

Packer and unpacker

Packer infeed with counter-rotating belt

Sorting packer infeed for three containers

BMS portal-type machine UNIPACK 2.0 – overview of technologies

Product advantages

- flexible

- Configurable axes

- Freely teachable positions

- Packing cam optimally designed to fit the product

- Fast adjustment of stops

- Future oriented

- Open design – “all-round view”

- Easy to clean

- Ergonomic handling when changing head and handling parts through optional handling parts magazine

Bottle table

- Integrated vibrator and completeness monitoring check

- Transfer panel between container transport and bottle table

- Container transport using flat-top chain of steel or plastic or mat conveyor, depending on the task.

Pack transport

- Integrated infeed and pack stopper

- Pack transport with flat-top chain of steel

- Optimised railing

Packing bells

Optimised long-term packing bells adjusted to fit the product range

- Packing bell with gripper finger

- Packing bell with inflatable sleeve

- Packing bells for PET

- Packing bells for clip-lock bottles

- Packing bell for tight spaces

- Special packing bells

Gripper heads

- Rigid and axially adjustable gripper heads

- Individually adjustable gripper heads for individual pack

- Gripper heads for carton

- Repacking gripper heads for carton

Additional equipment

- Automated label orientation

- Automated clip-lock rotation

- Full-crate monitoring

Select your language