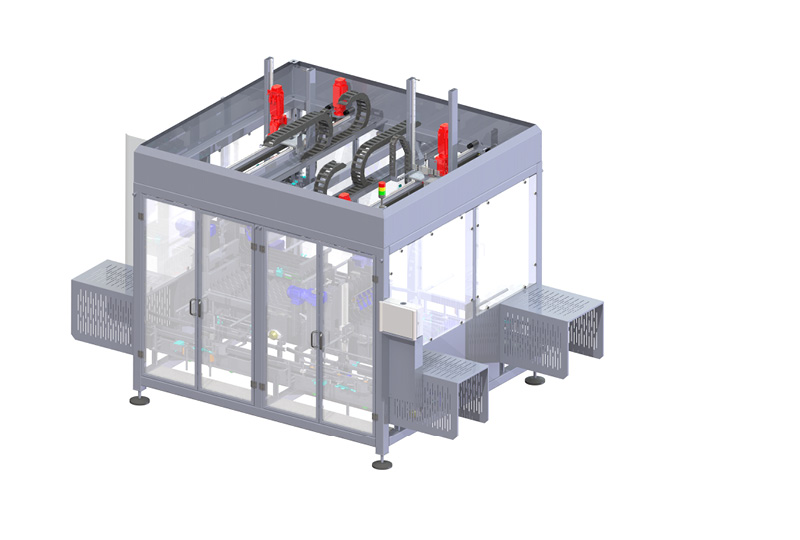

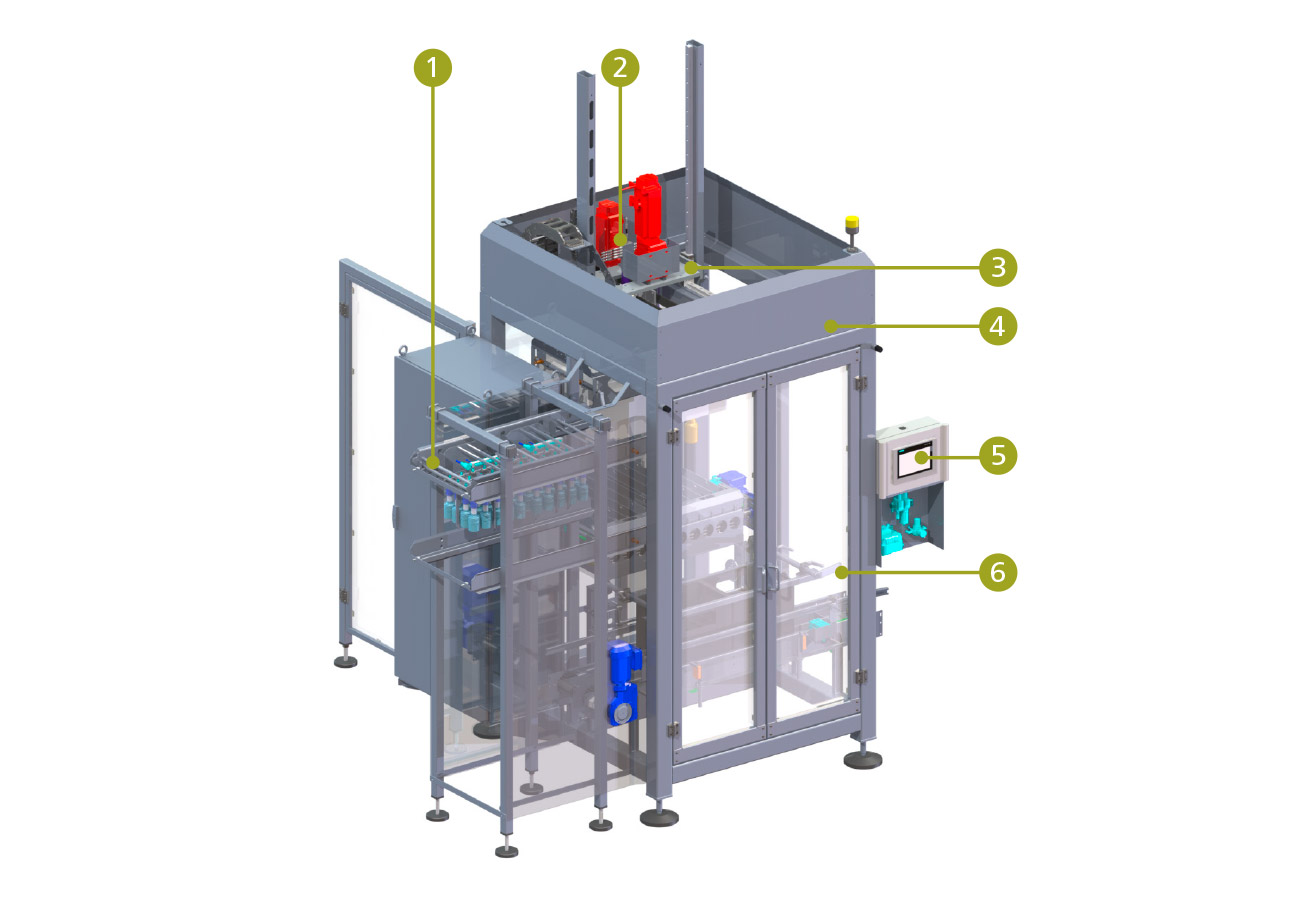

Portalpacker

UNIPACK 2.0

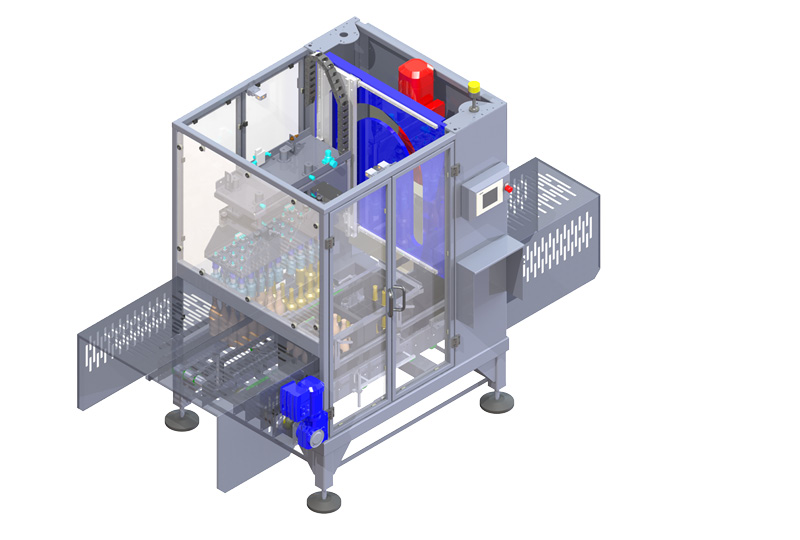

Mit der Packmaschinenneuentwicklung UNIPACK 2.0 reagiert BMS auf die steigende Produkt- und Behältervielfalt im kleinen und mittleren Leistungsbereich. Im Vergleich zur Vorgängermaschine ist der neue Portalpacker deutlich leistungsstärker und ab sofort für alle „Pick and Place”-Anwendungen in der Brau-, Getränke-, Molkerei- und Lebensmittelindustrie geeignet.

Der UNIPACK 2.0 bietet alle Vorzüge der bewährten Portalbauweise von BMS wie höchste Flexibilität, kurze Umrüstzeiten oder eine große Investitionssicherheit aufgrund der Nachrüstbarkeit der Portalachse.

Weitere charakteristische Merkmale des UNIPACK 2.0 sind seine modulare Ausführung, sein durchgängiges Hygiene-Design sowie sein hinsichtlich Konstruktion und Bedienung optimierter Aufbau.

BMS Portalmaschine UNIPACK 2.0 Technologien im Überblick

Produktvorteile

- flexibel

- Parametrierbare Achsen

- Frei teachbare Positionen

- Auf das Produkt optimierte Packkurve

- Schnellverstellung der Anschläge

- zukunftsorientiert

- Offene Bauweise – „Rundum Sicht”

- Gute Reinigbarkeit

- Ergonomische Handhabung bei Kopf und Garnituren Wechsel durch optionalem Garniturenmagazin Achsen

Flaschentisch

- Integrierter Rüttler und Vollzähligkeitskontrolle

- Überleitblech zwischen Behältertransport und Flaschentisch

- Behältertransport je nach Aufgabenstellung mittels Scharnierbandkette aus Stahl oder Kunststoff bzw. Mattenkette

Gebindetransport

- Integrierte Einlauf- und Gebindestopper

- Gebindetransport mit Stahl-Scharnierbandkette

- Optimierte Geländer

Packtulpen

Je nach Sortiment optimierte Langzeit Packtulpen

- Packtulpe mit Greiffinger

- Packtulpe mit aufblasbarer Manschette

- Packtulpen für PET

- Packtulpen für Bügelflaschen

- Packtulpe für enge Räume

- Selbst entwickelter Vakuumgreifer

- Sonderpacktulpen

Greiferköpfe

- Starre und axial verschiebbare Greiferköpfe

- Individual verschiebbare Greiferköpfe für individuelles Gebinde

- Greiferköpfe für Karton

- Umpackgreiferköpfe für Karton

Zusatzeinrichtungen

- Automatische Etikettenausrichtung

- Automatische Bügelausdrehung

- Vollkastenkontrolle

BMS packing machines of the UNIPACK series

Cam-controlled packing machine

UNIPACK 100

The BMS cam-controlled packing machine UNIPACK 100 has been specifically designed for small and medium capacities. Here the gripper head runs in high precision guides with a stable lever junction and is actuated via a solid steel cam. The installed asynchronous drive with enhanced energy efficiency and performance is also practically maintenance free. With its modular design based on a stable, welded distortion-free stainless steel structure, the UNIPACK 100 allows an individual adjustment to very different containers and packs. The UNIPACK 100 is available as a packing or unpacking unit and also for T-configuration or H-configuration.

UNIPACK portal-type machines – overview of technologies

Bottle table

- Integrated vibrator and completeness monitoring

- Transfer panel between container transport and bottle table

- Container transport equipped with flat-top chains of steel or plastic or mat-type conveyor, depending on the respective task

Pack transport

- Integrated infeed and pack stopper

- Pack transport with steel flat-top chain

- Optimised railing

Packing bells

Optimised long-term packing bells adjusted to suit the product range

- Packing bell with gripper finger

- Packing bell with inflatable sleeve

- Packing bells for PET

- Packing bells for clip-lock bottles

- Packing bells for tight spaces

- Self-developed vacuum gripper

- Special packing bells

Gripper heads

- Rigid and axially adjustable gripper heads

- Individually adjustable gripper heads for individual pack

- Gripper heads for carton

- Repacker gripper heads for carton

Additional equipment

- Automatic label orientation

- Automatic clip-lock rotation

- Crate full monitoring

BMS packing machines of the UNIPACK series

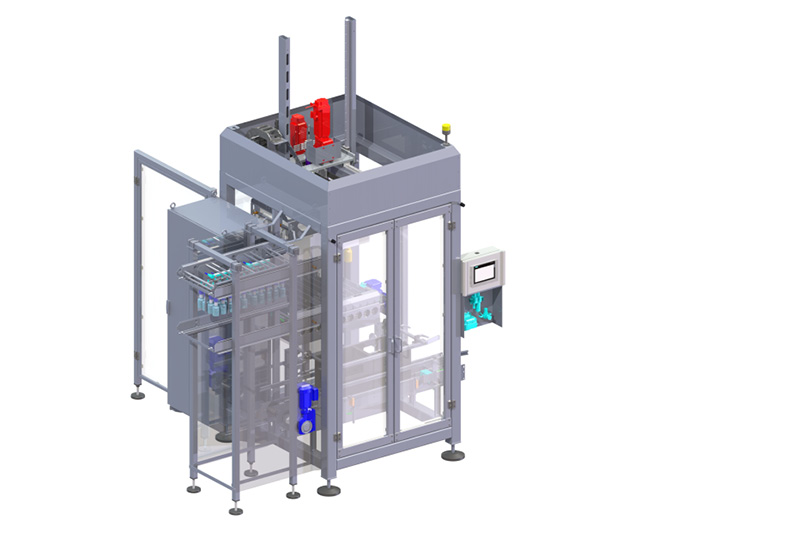

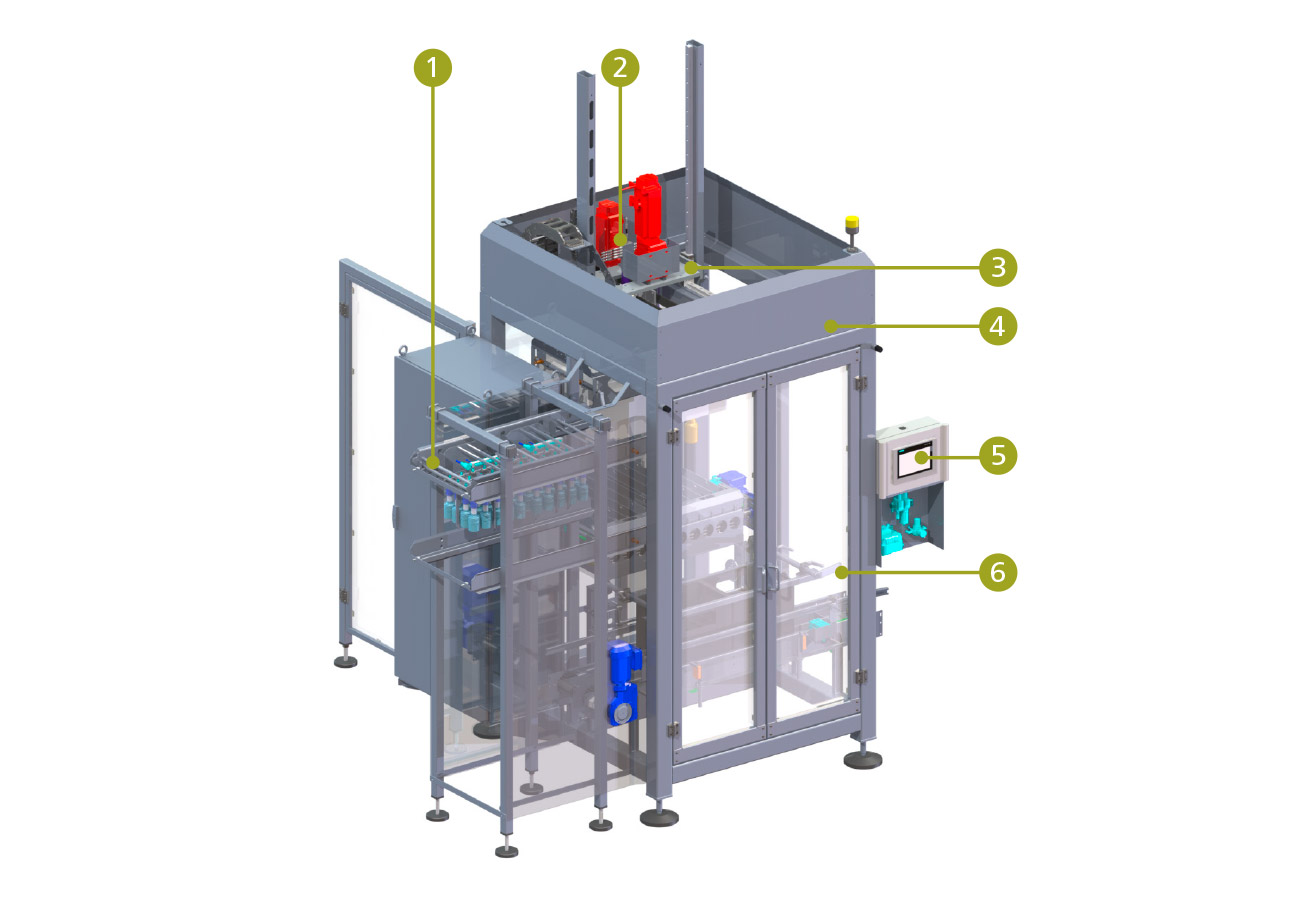

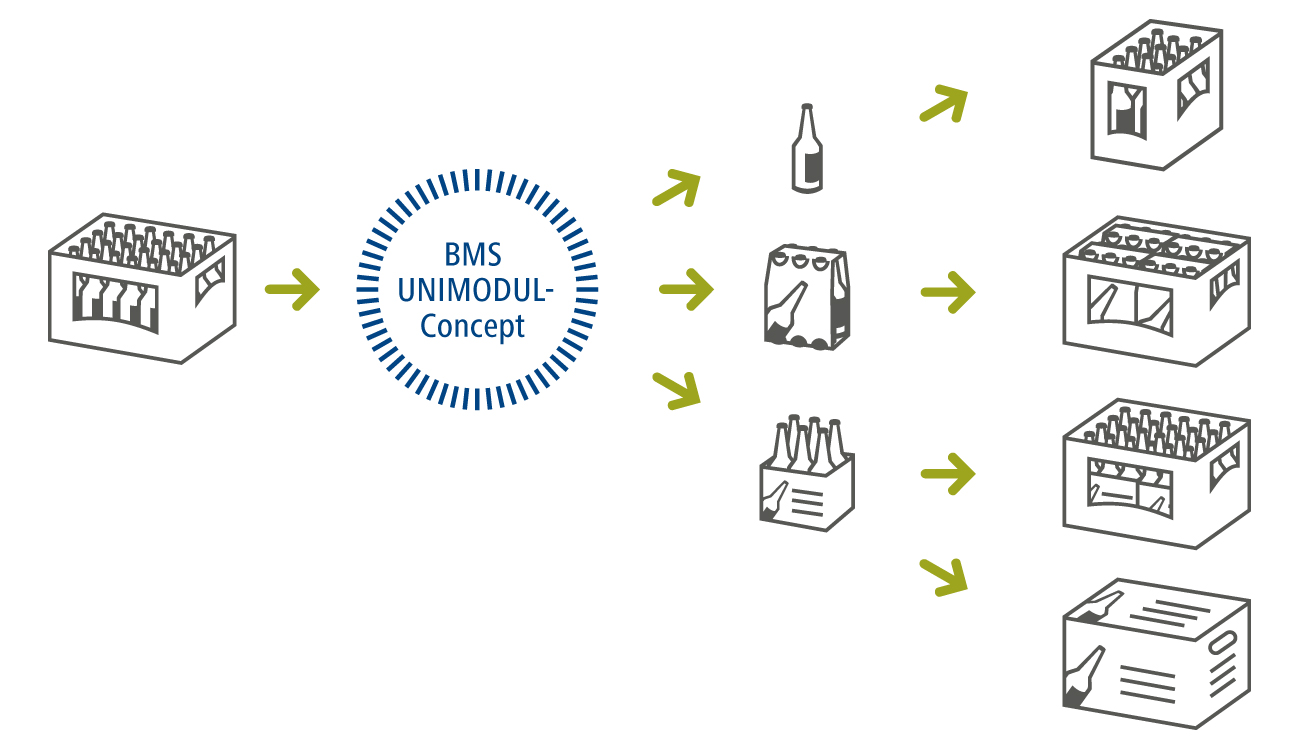

Unpacking, packing and repacking with the BMS portal-type machine UNIMODUL

Individually designed to meet your needs

The BMS UNIMODUL is a multifunctional combined packer, unpacker and repacker using the proven BMS technology. Through its flexible application it offers a high precision solution for many different tasks and, thanks to its mobility, it can be operated in different places. It has a touch panel with intuitive user prompting and logical diagnostic feedback. Every UNIMODUL is tailored to the customer’s individual needs and packaging variety – an absolute must with today’s many different packing applications.

The compact, space-saving portal design with highly dynamic servo-drives and optimal load distribution based on the unique bridge-type design make the UNIMODUL a multifunctional all-rounder.

- Optimal load distribution through a unique bridge-type design

- Highly dynamic servo-drives

- Compact, space-saving portal-type design

- Integrated machine protection

- Touch panel with intuitive user prompting and logical diagnostics feedback

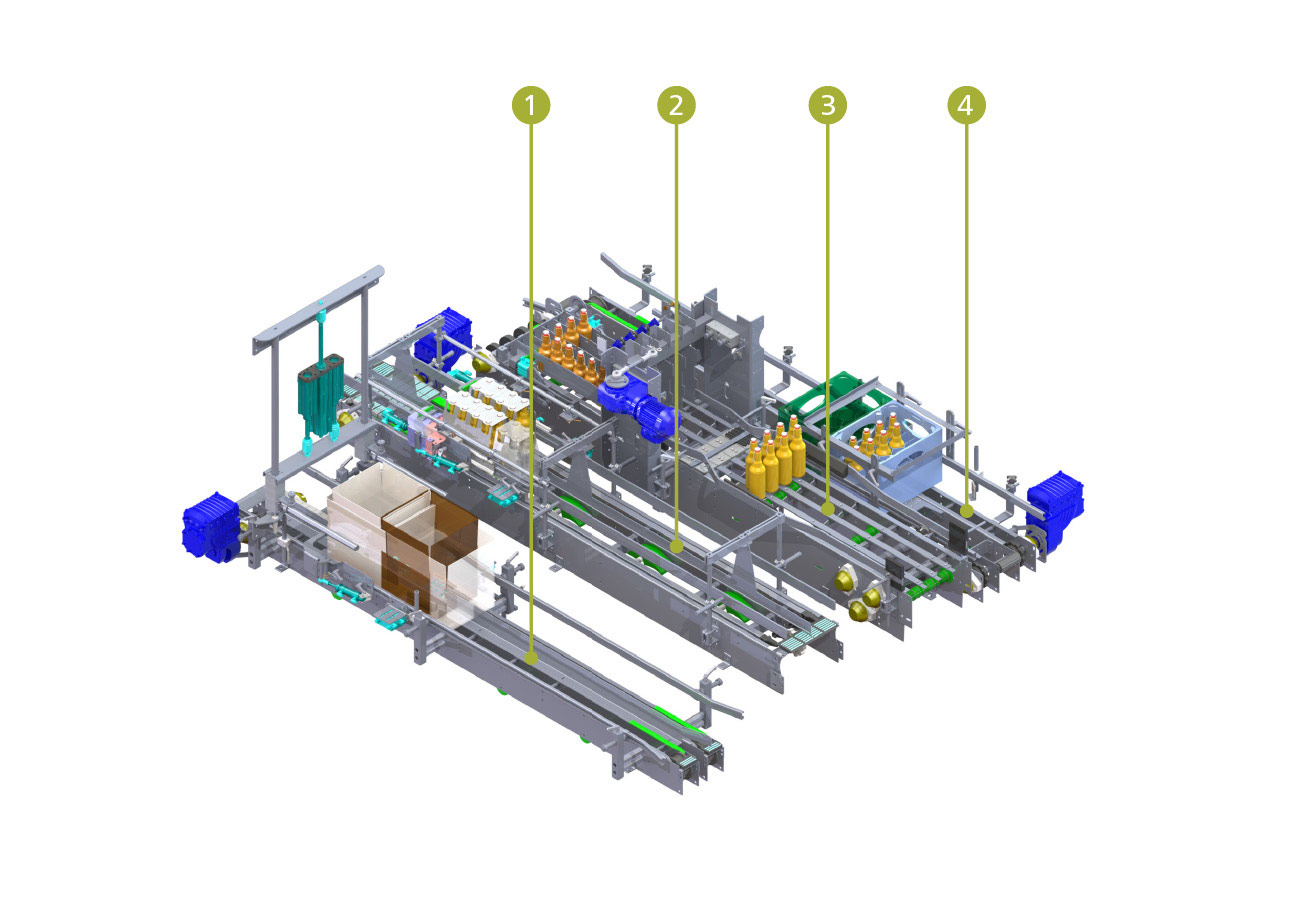

UNIMODUL inside

- Infeed final packing of packs

- Infeed final packing of packs (6-bottle pack; 4-bottle pack; ...)

- Infeed container conveyor, reversible

- Infeed repacking pack (e.g. full goods from storage)

UNIMODUL – unpacking, packing and repacking

SStandard packs to individual packs

Overview of UNIMODUL performance:

Repacking:

- Crate to carton

- Case to open basket

- Crate via multipack to case (pin partition)

- Crate (clip-lock bottle) to carton

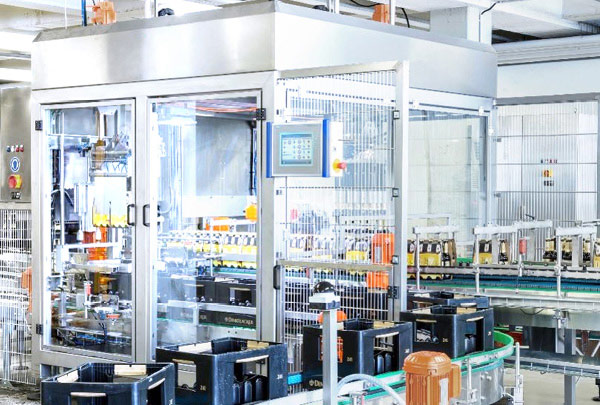

BMS UNIMODUL in operation

Repacking – crate to carton

Repacking – case to open basket

Repacking – crate via multipack to case (pin partition)

Repacking – 6-bottle pack with clip-lock bottles to carton

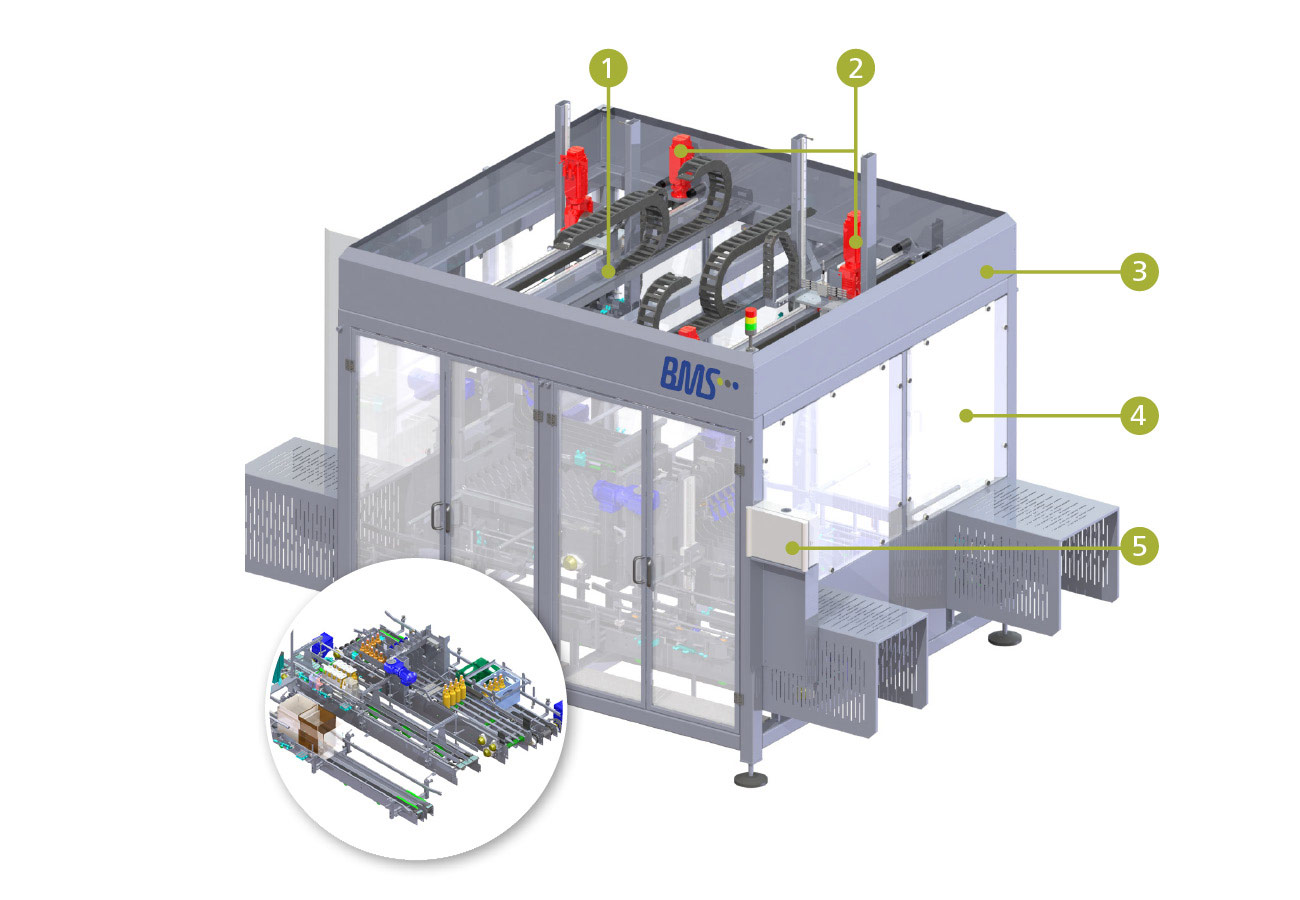

BMS packing machines of the UNIPACK series

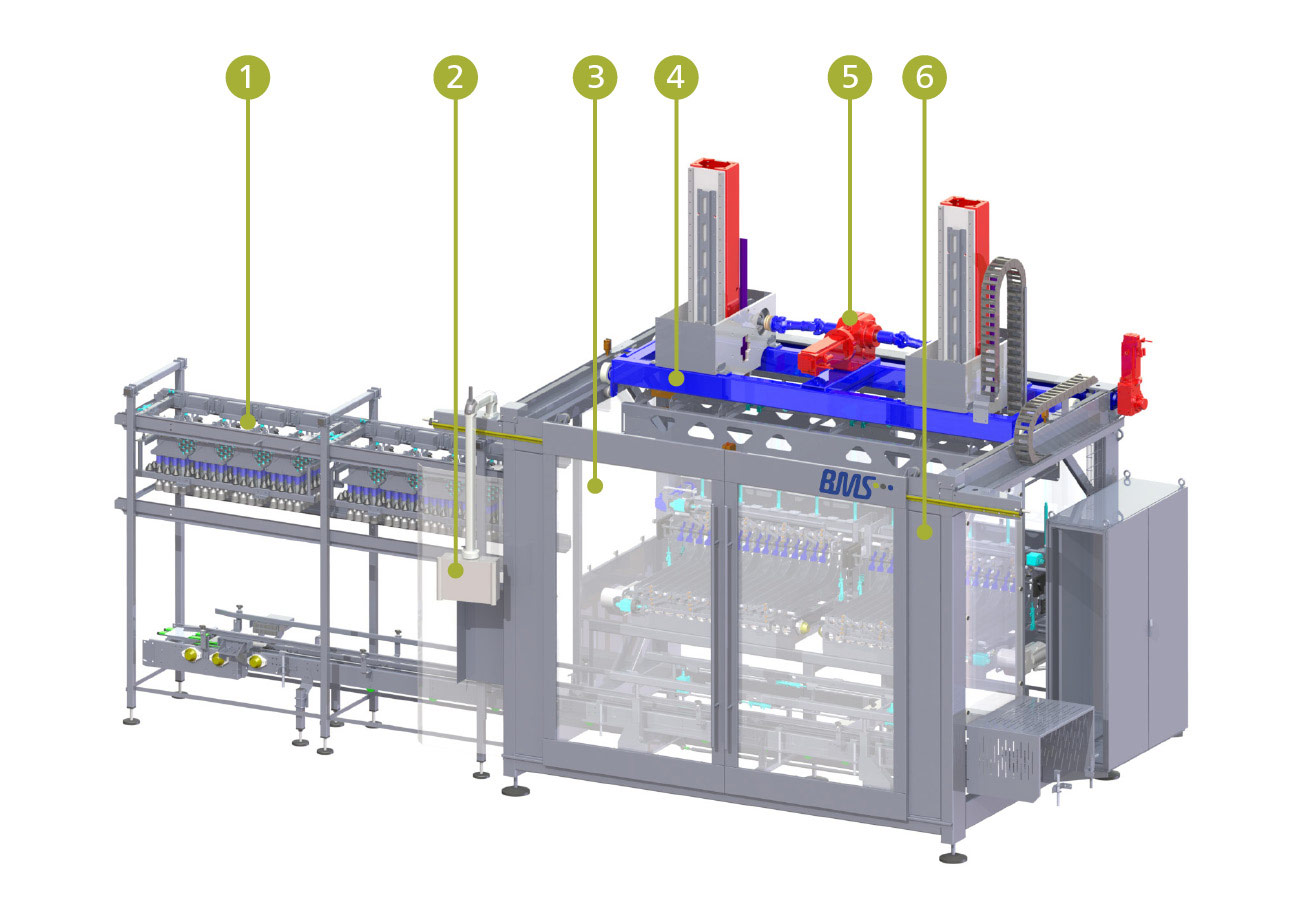

Portal-type packer

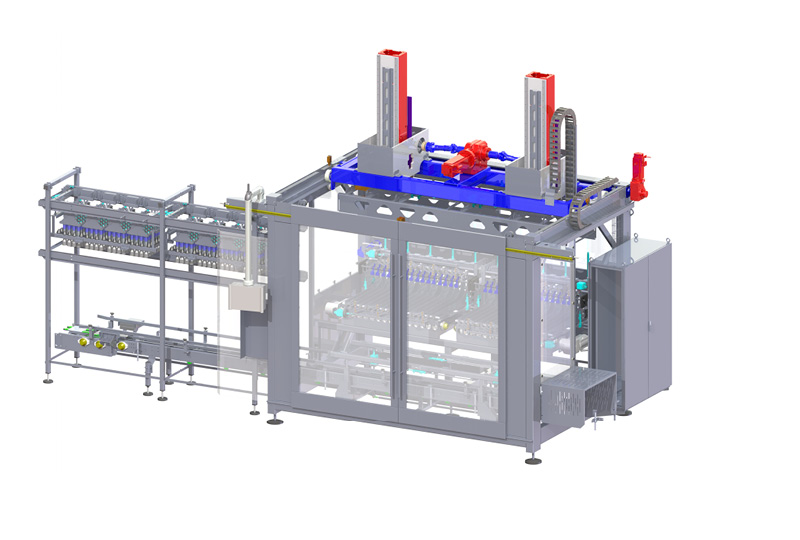

UNIPACK 103

The high performance packers of the type BMS Unipack 103 are very rugged and durable machines due to their portal-type design. The packing cam is freely programmable and is driven by maintenance-free drive systems. With its modular design, based on a stable, distortion-free stainless steel structure the UNIPACK 103 allows an individual adjustment to different container and pack sizes. By selecting the grouping length the BMS Unipack 103 can be individually adjusted to the prevailing circumstances and the customer’s required capacity. Small space requirement and integrated protective equipment are further advantages of the portal-type design.

- Integrated handling parts magazine

- Touch panel with intuitive user prompting and logical diagnostics feedback

- Integrated machine protection

- Optimal load distribution based on unique bridge-type design

- Highly dynamic servo-drives

- Compact, space-saving portal design

UNIPACK 103 in operation

Unpacker in two-lane H-configuration

Packing bells for clip-lock bottles with pneumatic bottle rotation

Packer with fully automated lane adjustment

Selective unpacking with individual-pack bell control

BMS portal-type machine UNIPACK 103 - overview of technologies

Bottle table

- Integrated vibrator and completeness monitoring

- Without transfer panel between container transport and bottle table – gap-free transition

- Container transport equipped with flat-top chain of steel or plastic or mat-type conveyor, depending on the task

Pack transport

- Integrated infeed and pack stopper

- Additional stopper as from 4 or more crates

- Pack transport with flat-top chain of steel

- Individual crate centring as from grouping length of four or more crates

- Motorised or pneumatically controlled crate centring frame in four-point design

Packing bells

Optimised long-term packing bells adjusted to fit the product range

- Packing bell with gripper finger

- Packing bell with inflatable sleeve

- Packing bells for PET

- Packing bells for clip-lock bottles

- Packing bell for tight spaces

- Self-developed vacuum gripper

- Special packing bells

Gripper heads

- Rigid and axially adjustable gripper heads

- Individually adjustable gripper heads for individual pack

- Gripper heads for carton

- Repacker gripper heads for six-packs

Additional equipment

- Automated label orientation

- Integrated gripper head magazine

- Automated gripper head change-over system

- Automated lane adjustment

- Handling parts magazine

BMS packing machines of the UNIPACK series

Portal-type packer

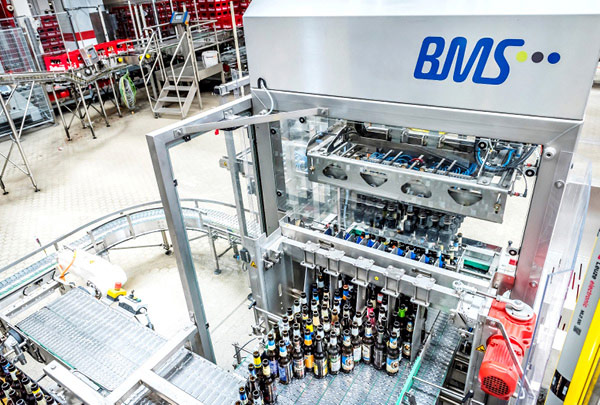

UNIPACK 2.0

With its new development of the packing machine UNIPACK 2.0 BMS has responded to the increase in variety of products and containers in the small and medium performance range. Compared to the previous model the new portal-type packer is much more powerful and can now be used for all pick-and-place applications in the brewing, beverage, dairy and food industry.

The UNIPACK 2.0 offers all advantages of the proven BMS portal design featuring maximum flexibility, short retooling times and high investment security based on the retrofit ability of the portal axis.

Other characteristic features of the UNIPACK 2.0 are its modular design, its consistent hygiene design as well as its optimised structure and operation.

- Integrated handling parts magazine

- Highly dynamic servo-drives

- Optimal load distribution based on the unique bridge-type design

- Compact, space-saving portal design

- Touch panel with intuitive user prompting and logical diagnostics feedback

- Integrated machine protection

BMS portal-type machine UNIPACK 2.0 in operation

Packer

Packer and unpacker

Packer infeed with counter-rotating belt

Sorting packer infeed for three containers

BMS portal-type machine UNIPACK 2.0 – overview of technologies

Product advantages

- flexible

- Configurable axes

- Freely teachable positions

- Packing cam optimally designed to fit the product

- Fast adjustment of stops

- Future oriented

- Open design – “all-round view”

- Easy to clean

- Ergonomic handling when changing head and handling parts through optional handling parts magazine

Bottle table

- Integrated vibrator and completeness monitoring check

- Transfer panel between container transport and bottle table

- Container transport using flat-top chain of steel or plastic or mat conveyor, depending on the task.

Pack transport

- Integrated infeed and pack stopper

- Pack transport with flat-top chain of steel

- Optimised railing

Packing bells

Optimised long-term packing bells adjusted to fit the product range

- Packing bell with gripper finger

- Packing bell with inflatable sleeve

- Packing bells for PET

- Packing bells for clip-lock bottles

- Packing bell for tight spaces

- Special packing bells

Gripper heads

- Rigid and axially adjustable gripper heads

- Individually adjustable gripper heads for individual pack

- Gripper heads for carton

- Repacking gripper heads for carton

Additional equipment

- Automated label orientation

- Automated clip-lock rotation

- Full-crate monitoring